Selecting the appropriate diamond saw blade is critical for achieving optimal cutting results across the diverse array of materials encountered. Experts advise that this process requires carefully weighing multiple factors.

The hardness of the material being cut. For exceptionally hard substances like marble and granite, blades with a higher concentration of diamond particles and superior hardness should be employed, typically manufactured using advanced electroplating or sintering techniques. Conversely, when cutting softer materials like wood or plastics, blades with a moderate diamond content may suffice.

Next, the required level of cutting precision must be considered. High-precision cuts necessitate blades with uniformly distributed, fine diamond particles, while lower-precision applications can utilize coarser grit blades to achieve faster cutting speeds. It's noteworthy that certain materials, such as silicon carbide, exhibit corrosive properties, thus mandating the use of diamond blades with enhanced corrosion resistance.

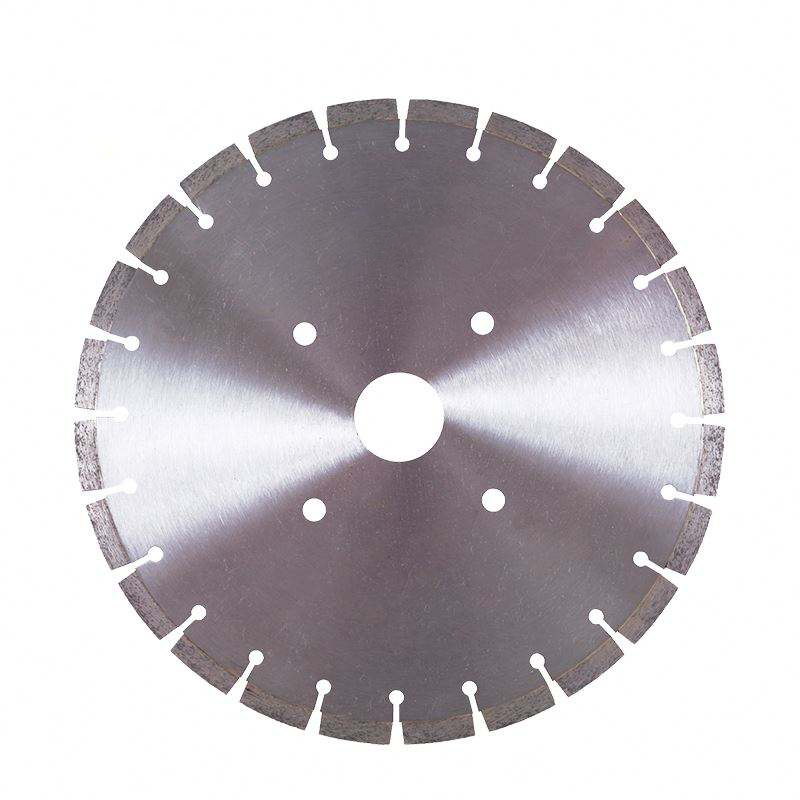

The cutting depth is another crucial factor. As the depth increases, thicker blades with greater rigidity become necessary to prevent excessive deformation or breakage. Additionally, for curved cutting applications, specialized circular diamond blades must be selected.

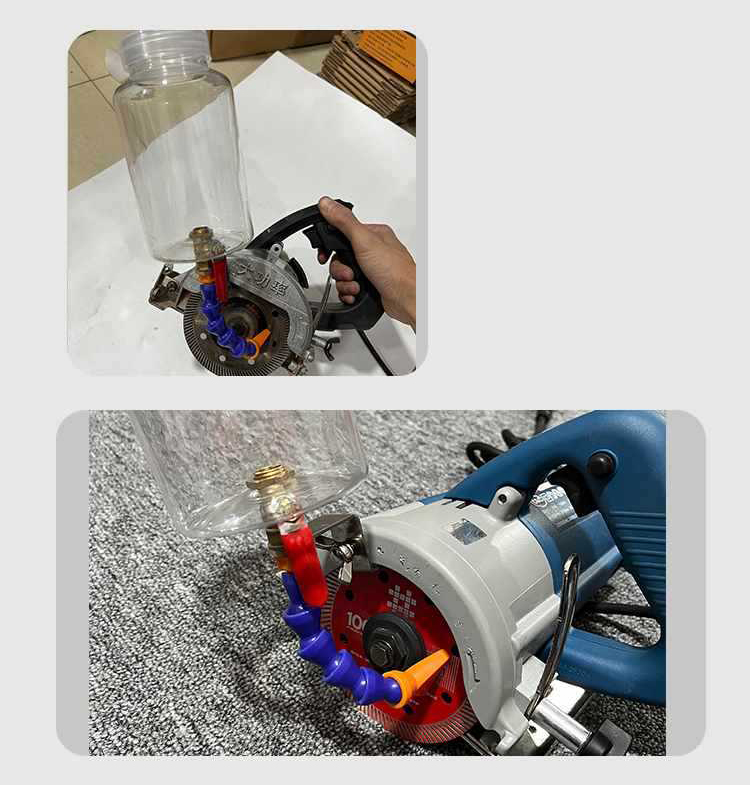

Cooling requirements can also vary across different scenarios. Some materials generate high temperatures during the cutting process, necessitating water-cooling systems to lower the blade temperature. In such cases, diamond blades with integrated cooling holes become an indispensable choice.

It is advisable to consult industry professionals for their recommendations on blade selection for specific materials. This ensures adherence to safety standards, mitigating the risk of accidents. Mastering these nuances is pivotal in guaranteeing cutting performance meets the desired standards.

By meticulously accounting for material hardness, precision needs, corrosion resistance, cutting depth, cooling demands, and expert guidance, one can navigate the intricate process of diamond blade selection with confidence, optimizing results across an extensive range of applications.