- 1. Introduction of Diamond Saw Blades

- 2. The History and Technological Evolution of Diamond Saw Blades

- 3. Classification and Applications of Diamond Saw Blades

- 4. Optimization of Diamond Saw Blade Manufacturing Processes

- 5. Market Trends and Prospects for Diamond Saw Blade Applications

- 6. How to Choose the Right Diamond Saw Blade

- 7. Maintenance and Safety Guidelines for Diamond Saw Blades

- 8. Conclusion

- 9. Frequently Asked Questions (FAQ)

1. Introduction of Diamond Saw Blades

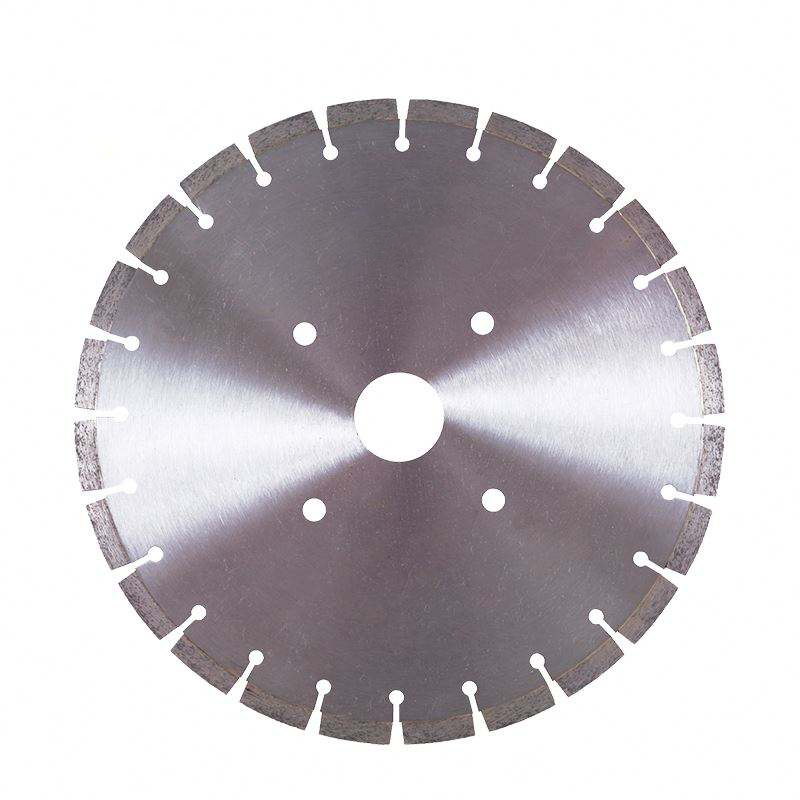

What are Diamond Saw Blades?

Diamond saw blades are widely used tools for cutting hard materials, employing synthetic or natural diamonds as the cutting medium. Due to the extreme hardness and abrasion resistance of diamonds, these blades effortlessly cut through concrete, stone, ceramics, glass, and more. The design and manufacturing of diamond saw blades incorporate advanced materials and precision engineering to ensure their efficiency and durability in various harsh conditions.

The Importance of Diamond Saw Blades in Industry

In modern industry, diamond saw blades are indispensable tools. From construction and stone processing to high-end manufacturing, diamond saw blades play a vital role. Their exceptional cutting capabilities and longevity not only enhance production efficiency but also reduce production costs, driving the development of several industries. As technology advances, the range of applications for diamond saw blades continues to expand, ensuring their significant role in future industrial progress.

2. The History and Technological Evolution of Diamond Saw Blades

Diamond saw blades are advanced cutting tools designed for precision and efficiency, using tiny diamond particles to slice through hard materials like stone, concrete, and ceramics. Originating from ancient techniques, modern diamond saw blades began to take shape in the mid-20th century, notably with the introduction of synthetic diamonds in the 1940s, which made these tools more accessible. Their manufacturing involves several meticulous steps, including core preparation, segment creation with diamond and metal powders, and rigorous quality control. Recent innovations have led to improved diamond synthesis, advanced bonding techniques, optimized designs, and smart technology that monitors performance. These developments enhance the efficiency, durability, and versatility of diamond saw blades, making them indispensable in construction and stone-working industries.

Read more about 《Diamond Saw Blades: Cutting-Edge Technology》

3. Classification and Applications of Diamond Saw Blades

Diamond saw blades are crucial tools for efficiently cutting various materials, and they can be classified based on multiple criteria, including purpose, matrix material, diamond grit size, blade shape, cutting method, diameter, cutting depth, manufacturing process, and diamond distribution. Understanding these classifications allows users to choose the most suitable blade for their needs, ultimately enhancing cutting performance and quality.

Classification by purpose includes general-purpose, professional, and precision cutting blades. General-purpose blades are versatile for materials like wood and plastic, making them ideal for DIY projects. Professional blades are specifically designed for tougher materials such as concrete and stone, commonly used in construction and renovation. Precision cutting blades are tailored for high-accuracy tasks found in laboratories and fine manufacturing, ensuring superior precision.

The classification also includes distinctions based on matrix material, grit size, shape, cutting method, and other features. Metal matrix blades are durable for hard materials, while resin matrix blades work well with softer substances. Grit sizes range from coarse to fine, affecting cutting speed and surface finish. Blade shapes, such as flat, wavy, and turbo, cater to different cutting needs and environments. Additionally, cutting methods (dry, wet, or dual-use), blade diameters (small, medium, or large), and manufacturing processes (sintered, electroplated, or laser welded) further define the capabilities of each blade. By understanding these classifications, users can make informed decisions to achieve optimal results for their specific cutting tasks.

Electroplated diamond cutting blade

Different classifications of diamond saw blades offer distinct advantages in specific applications. First, by purpose, professional cutting blades demonstrate higher durability and precision when cutting concrete and stone, making them ideal for construction sites and stone processing plants, while general-purpose blades are suitable for home DIY projects and small-scale tasks. Second, classified by matrix material, metal matrix blades provide good durability and heat dissipation when cutting hard materials, whereas resin matrix blades are better for cutting softer materials like ceramics and glass, reducing cutting temperatures. Third, by diamond grit size, coarse grit blades allow for quick cutting of concrete surfaces but leave a rough finish, while fine grit blades provide a smoother surface, making them ideal for precision tasks like cutting tiles and glass. Additionally, the blade's shape and cutting method also influence application efficiency; for example, turbo blades excel in prolonged cutting tasks, while wet cutting blades effectively lower cutting temperatures and reduce dust. Therefore, selecting the appropriate classification of diamond saw blades can significantly enhance cutting performance and work efficiency.

Read more about 《Diamond Saw Blade Classification Methods》

4. Optimization of Diamond Saw Blade Manufacturing Processes

4.1 Optimizing the Sintering Process of Diamond Segments

Optimizing the sintering process of diamond segments is crucial for enhancing bond strength and cutting efficiency. Using metal powders that do not chemically react with diamonds during high-temperature sintering can prevent damage to the diamonds. However, if the matrix powder lacks a chemical reaction with the diamond, the holding power relies solely on weak mechanical embedding, which can lead to diamond detachment and reduced blade lifespan. Conversely, if the metal powder reacts with the diamond, forming strong chemical bonds, it significantly enhances the matrix's holding power, ensuring the diamonds remain securely in place during use and improving the blade's overall performance.

However, controlling the reaction between the metal powder and diamond is essential to avoid excessive carbonization, which can weaken the diamonds and reduce the blade's efficiency. Analysis indicates that at temperatures above 900°C, certain metals like iron can cause diamond infiltration, leading to surface erosion. To mitigate this, the reaction speed must be carefully managed, and the addition of other chemical elements, such as titanium, can enhance the diamond matrix's holding power. Titanium, a rare metal, is often used in the production of diamond segments, which are sintered under pressure and cooled to optimize their strength and durability before use.

Read more about 《Optimizing the Sintering Process of Diamond Segments: Enhancing Bond Strength and Cutting Efficiency》

4.2 Key Points of Vacuum Brazing Technology in Diamond Tools

The vacuum brazing process for diamond tools involves several critical steps to ensure effective bonding and durability. It begins with surface treatment of the diamond substrate to eliminate impurities, followed by the preparation of appropriate brazing and filling materials, such as rhenium for brazing and copper or silver for filling. The assembled joint is then placed in a vacuum furnace, where gases are evacuated to prevent oxidation and carburization, before heating to the specified brazing temperature—typically between 1100°C and 1500°C. Key considerations during this process include avoiding oxidation effects, selecting suitable temperatures and pressures based on the materials used, and conducting thorough quality inspections after brazing. Inspection methods such as fracture observation, metallographic analysis, and mechanical property testing are employed to assess the integrity and performance of the brazed joints, ensuring the reliability of the diamond tools.

Read more about 《Technology and key points of vacuum brazing diamond tools》

5. Market Trends and Prospects for Diamond Saw Blade Applications

5.1 The Use of Diamond Cutting Tools in the Hardware Tools Industry

Diamond cutting tools are becoming increasingly prevalent in the hardware tools industry, driven by their exceptional performance and numerous advantages. Diamond, recognized as the hardest natural material with a Mohs hardness of 10, offers unparalleled hardness and wear resistance. These properties make diamond cutting tools ideal for machining extremely hard materials such as ceramics, composites, and super-alloys. Unlike conventional cutting tools, which can wear down or become damaged quickly when working with these tough materials, diamond tools maintain their integrity and effectiveness, ensuring consistent performance and longevity.

One of the standout benefits of diamond cutting tools is their extended tool life. The extreme hardness and wear resistance of diamond enable these tools to retain their sharpness and cutting edges far longer than traditional tools made from high-speed steel or cemented carbides. This longevity translates to fewer tool changes, reduced downtime, and increased overall productivity. Additionally, diamond cutting tools can achieve higher material removal rates due to their ability to operate at higher cutting speeds and feed rates. Their excellent thermal conductivity helps dissipate heat efficiently, allowing for faster machining processes without compromising tool performance or workpiece quality.

In terms of surface finish, diamond cutting tools excel in producing superior results. The sharp and precise cutting edges of diamond tools ensure that workpieces receive an excellent surface finish, which is crucial for industries where surface quality is paramount, such as aerospace and medical device manufacturing. This high level of precision not only enhances the aesthetic appeal of the final product but also improves its functional performance by reducing surface imperfections that could lead to failures or inefficiencies.

While the initial cost of diamond cutting tools is higher compared to conventional alternatives, their extended tool life and enhanced productivity offer significant cost-effectiveness over time. The reduced need for frequent tool replacements and the ability to complete machining tasks more efficiently can offset the higher upfront investment, making diamond cutting tools a financially viable option for high-volume or high-value machining operations. Furthermore, advancements in diamond synthesis have made synthetic diamonds more accessible and affordable, broadening the range of applications where diamond cutting tools can be economically utilized. As manufacturing industries continue to demand higher precision, better surface finishes, and improved productivity, the adoption of diamond cutting tools is expected to grow, particularly in the machining of advanced materials and components that require stringent quality standards.

Read more about 《why diamond cutting tools are increasingly being used in the hardware tools industry》

5.2 The Rise of China's Synthetic Diamond Industry and Its Application Prospects

Diamond cutting tools are gaining popularity in the hardware tools industry for several compelling reasons. First, diamonds possess exceptional hardness and wear resistance, ranking a perfect 10 on the Mohs hardness scale. This makes them particularly effective for machining hard materials such as ceramics, composites, and super-alloys, which can quickly wear down conventional cutting tools made from high-speed steel or cemented carbides. Additionally, diamond tools maintain their sharpness and cutting edges for much longer periods, resulting in extended tool life, fewer tool changes, and improved productivity. Their ability to produce superior surface finishes is also crucial, especially in industries like aerospace and medical, where high-quality surface quality is essential.

Moreover, diamond cutting tools enable higher material removal rates due to their hardness and excellent thermal conductivity, allowing for faster cutting speeds and feed rates compared to traditional tools. While the initial cost of diamond cutting tools is higher, their longevity and enhanced productivity often justify the expense, particularly for high-volume or high-value machining operations. The advancements in synthetic diamond production have made these tools more accessible and economically viable for a broader range of applications. As manufacturing industries increasingly prioritize precision, superior surface finishes, and overall productivity, the demand for diamond cutting tools is expected to continue rising, especially in the machining of advanced materials with stringent quality requirements.

Read more about 《The Rise of China's Synthetic Diamond Industry and Its Application Prospects》

6. How to Choose the Right Diamond Saw Blade

6.1 Tips for Selecting Diamond Saw Blades Based on Materials

Selecting the right diamond saw blade is essential for achieving optimal cutting results across various materials, and it involves considering multiple factors. First, the hardness of the material being cut plays a significant role; for hard substances like marble and granite, blades with a higher concentration of diamond particles are necessary, while softer materials like wood may only require blades with moderate diamond content. Additionally, the required cutting precision must be taken into account, with high-precision cuts needing blades with fine, uniformly distributed diamond particles, whereas coarser grit blades can be used for faster cuts in less precise applications. The cutting depth is also crucial, as thicker, more rigid blades are needed for deeper cuts, and specialized blades are required for curved cutting tasks. Cooling requirements can vary as well, with some materials generating heat that necessitates water-cooling systems, making diamond blades with integrated cooling holes advantageous. Consulting industry professionals for specific recommendations can enhance safety and performance, allowing users to navigate the intricate selection process confidently and optimize cutting results across a wide range of applications.

Read more about 《Mastering the Art of Diamond Blade Selection for Optimal Cutting Across Materials》

6.2 Common Issues and Solutions in Stone Cutting with Diamond Saw Blades

When using diamond saw blades for stone cutting, several common issues can arise, including blade burning, sparking, blade jumping, segment loss, and lack of sharpness. Blade burning is characterized by the blade tip turning red or black due to excessive heat, which can be caused by factors such as a hard matrix, insufficient diamond exposure, low cutting speed, or inadequate blade rigidity. Sparking, or fire streaking, results from improper diamond distribution or abnormal grit size, leading to intense cutting action that can create black marks on the stone surface. Blade jumping indicates instability during cutting, often due to improper diamond exposure or sudden changes in the stone structure, while segment loss can occur from welding issues, excessive cutting depth, or insufficient blade rigidity.

Lack of sharpness is another prevalent problem, resulting in slow cutting speeds and reduced efficiency. This dulling can be attributed to temperature gradients, uneven distribution of low-melting additives during sintering, and mechanical property changes that weaken the blade. Accumulated heat and vibrations can further degrade the blade's performance by weakening the matrix's holding strength. Other contributing factors to dulling include insufficient diamond concentration, an improper grit ratio, and inadequate matrix support. Understanding these issues is essential for optimizing diamond blade performance and ensuring efficient stone cutting operations.

Read more about 《Common cutting issues with diamond saw blades during stone cutting》

7. Maintenance and Safety Guidelines for Diamond Saw Blades

7.1 How to Assess the Quality of Diamond Saw Blades

Assessing the quality of diamond saw blades is crucial for ensuring optimal cutting performance and longevity, especially when working with hard and brittle materials like concrete, stone, and ceramics. One of the primary indicators of a high-quality diamond saw blade is the concentration of diamond grains on the blade’s head. A proper concentration ensures that the blade maintains its cutting power and wears evenly over time. Conversely, a low concentration can lead to rapid wear and diminished cutting efficiency, while an excessively high concentration might reduce sharpness and compromise stability. Additionally, the uniform distribution of diamond grains across the blade head is essential. Evenly distributed diamonds facilitate smoother cutting operations and prevent uneven wear, which can result in decreased lifespan and inconsistent performance during high-intensity use.

The structural integrity of the diamond saw blade is another critical factor in quality assessment. Inspecting the welding seams is essential; they should be intact and neatly aligned with the substrate groove to ensure effective chip removal and heat dissipation. Poorly welded seams can lead to blade detachment and compromised cutting ability. Furthermore, the alignment of the blade head with the substrate on a horizontal plane should be precise. Any irregularities or unevenness can cause the blade to loosen during operation, increasing the risk of edge collapse or complete blade failure. Additionally, comparing the thickness of the blade head to the substrate provides insight into the blade’s design and durability. For instance, a granite blade typically has a blade head that is about 1mm thicker than the substrate, enhancing both the blade’s lifespan and its resistance to damage.

Balancing blade sharpness and wear resistance is essential for selecting the right diamond saw blade for specific applications. While sharper blades offer better cutting performance, they may wear out faster compared to blades designed for extended lifespan. It is important to choose a blade that meets the expected lifespan and maintains adequate sharpness under varying external conditions such as machine performance, operator technique, and material hardness. Manufacturers often provide a range of blade types, including sharp, lifespan, comprehensive, and cost-effective options, to cater to different cutting needs. Additionally, while visual inspections based on appearance defects, saw tooth shape, and blade body material can provide preliminary assessments, they should be complemented with the aforementioned criteria to ensure a comprehensive evaluation of the blade’s quality.

Read more about 《How to Assess the Quality of Diamond Saw Blades》

7.2 Safety Usage Guidelines for Diamond Saw Blades

When operating small-diameter diamond saw blades for cutting materials such as marble, granite, concrete, refractory materials, and ceramics, safety and proper maintenance are paramount. Operators must always wear appropriate protective equipment, including safety shoes, safety glasses, hard hats, and ear protection, to safeguard against potential hazards. Additionally, ensuring that the cutting machine is equipped with protective covers or other safety devices is essential to prevent accidents. Before each use, thoroughly inspect the saw blade for any signs of damage or severe deformation. A damaged blade should never be used, as it can compromise cutting performance and safety. It is also crucial to keep the chuck of the cutting machine clean and free from debris, and to check the spindle bearings, spindle, and sleeve for any signs of excessive wear, replacing parts as necessary to maintain optimal functionality.

The direction of the saw blade is marked on the disk face

Proper installation and operation techniques significantly enhance the safety and effectiveness of diamond saw blades. When mounting the blade, ensure that the direction marked on the blade aligns with the rotation direction of the cutting machine to avoid cutting difficulties and potential blade failure. For wet cutting applications, always provide sufficient cooling water during operation to prevent overheating and extend the blade’s lifespan. In dry cutting scenarios, implement periodic idling every 10 to 15 seconds to allow the blade to cool, and consider making incremental cuts for deeper materials to reduce stress on the blade. Avoid curved cutting and side grinding, as these actions can lead to blade cracking, chipping, or base fractures. Additionally, maintain a safe cutting angle and depth to prevent the blade from becoming too stressed, and always ensure that your body and the blade are not on the same plane to minimize the risk of injury.

Regular maintenance and vigilant monitoring during use are critical for sustaining blade performance and safety. If a diamond saw blade becomes dull due to blockage, it can be re-sharpened using a ceramic grinding wheel or refractory brick by making approximately ten passes to restore its sharpness. Should you encounter unusual noises or severe vibrations during cutting, immediately stop and inspect the blade for cracks or chipping, replacing it if any damage is found. Ensuring that the blade aperture matches the spindle size is also important; using appropriately sized washers can help stabilize the blade, but always check for secure fastening to prevent shaking and potential blade detachment. By adhering to these safe usage guidelines, operators can prolong the lifespan of diamond saw blades, enhance cutting effectiveness, and maintain a safe working environment.

Read more about 《Safety Usage Guidelines for Diamond Saw Blades》

8. Conclusion

Future Trends in Diamond Saw Blade Development

With ongoing advancements in material science and manufacturing technologies, the performance of diamond saw blades will continue to improve. In the future, as demands for environmental conservation and efficiency increase, diamond saw blades with low energy consumption and high cutting efficiency will become more popular. Additionally, the application of new materials and coating technologies will further enhance the durability and applicability of the blades, meeting increasingly complex and varied cutting needs.

The Importance of Choosing High-Quality Diamond Saw Blades

Among the plethora of diamond saw blade products, selecting a high-quality blade is crucial. A superior blade not only ensures precision and efficiency in cutting but also extends the tool’s lifespan and reduces overall operational costs. Therefore, understanding the characteristics and application scenarios of diamond saw blades is essential for users to make the best choices, whether at the time of purchase or during use.

9. Frequently Asked Questions (FAQ)

9.1 What materials are suitable for diamond saw blades?

Diamond saw blades are primarily used to cut hard and brittle materials, such as concrete, granite, marble, ceramics, glass, and bricks.

9.2 How can you determine the wear level of a diamond saw blade?

The wear condition of a blade can typically be assessed by observing the cutting efficiency and the quality of the cut surfaces. If the cutting speed decreases significantly or the cut surfaces become rough, it may indicate that the blade is heavily worn and needs to be replaced or repaired.

9.3 How long is the lifespan of a diamond saw blade?

The lifespan of a saw blade depends on several factors, including the hardness of the material, cutting speed, cooling conditions, etc. Generally, a high-quality diamond saw blade can last for tens to hundreds of hours under normal usage conditions.

9.4 How should diamond saw blades be stored properly?

Diamond saw blades should be stored in a dry, ventilated environment to prevent moisture and sun exposure. When storing, place the blades on a specialized rack to avoid direct contact with other metal tools, which could damage the cutting edges.