Diamond saw blades are indispensable tools for cutting a diverse range of materials, including concrete, asphalt, stone, and metal. Understanding the primary components of diamond blades is essential for comprehending their functionality and for selecting the appropriate blade to suit specific cutting requirements.

- Diamonds

The predominant constituent of a diamond saw blade is, naturally, the diamonds themselves. Diamonds serve as the active cutting agents, necessitating the selection of blades featuring high-quality, industrial-grade diamonds. Typically, diamonds are embedded within the segments or ridges of the blade, or form a continuous rim encircling the blade's circumference.

- Metal Core

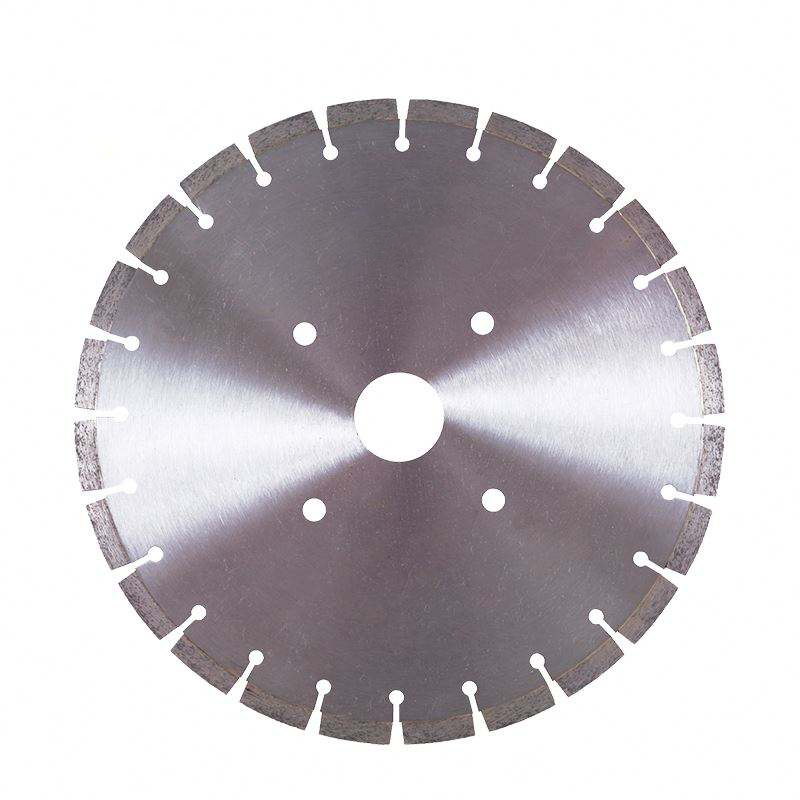

The metal core serves as the backbone of the blade, furnishing stability and support for the diamonds. Usually crafted from high-quality steel or another metal engineered to withstand cutting stresses, the thickness and strength of the metal core vary based on blade type and the materials designated for cutting.

- Segments or Ridges

Segments or ridges are the raised portions of the blade containing the embedded diamonds. These components are engineered to deliver aggressive cutting action while securing the diamonds in place during cutting. The number, size, and arrangement of segments or ridges vary according to blade type and the materials targeted for cutting.

- Continuous Rim

A feature found in certain types of diamond blades, such as continuous rim blades, is the continuous rim itself. Housing a continuous row of diamonds, this design ensures a smooth and precise cut. The size and arrangement of diamonds within the continuous rim are contingent upon blade type and the materials slated for cutting.

- Cooling System

During cutting, diamond blades generate substantial heat, which may accelerate blade wear and diminish diamond cutting effectiveness. To mitigate this issue, many diamond blades incorporate a cooling system, such as water channels or air vents, to regulate blade temperature during operation.

- Flange

The flange represents the component of the blade that affixes it to the cutting machine, such as a saw or grinder. Designed to securely fit the machine and furnish stability and support during cutting, flange size and shape vary depending on blade type and the cutting machine for which it is intended.